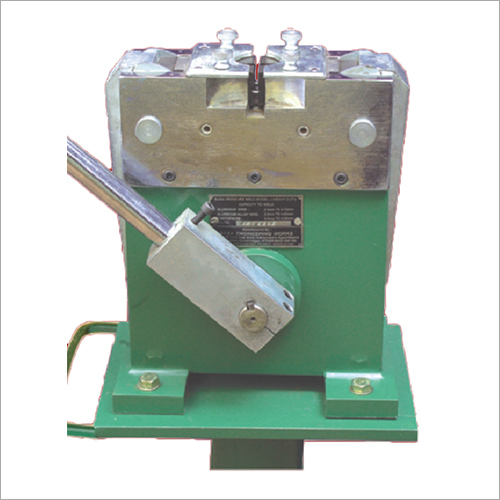

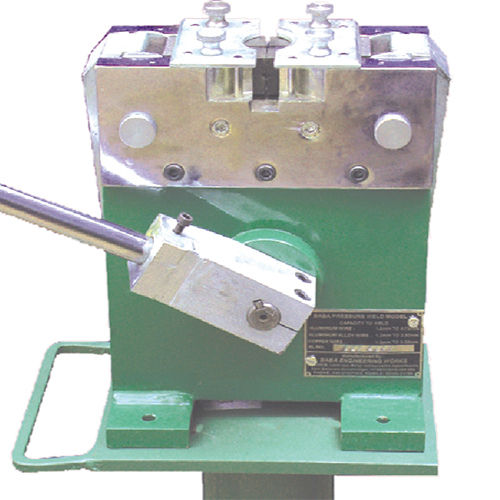

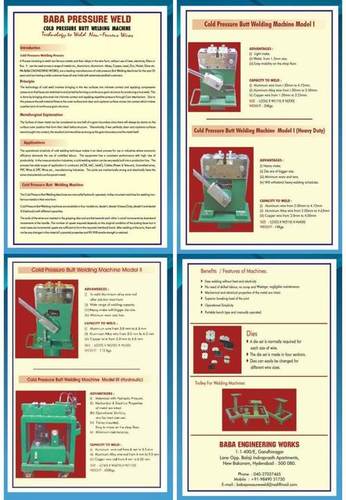

Cold Pressure Butt Welding Machine Model-I (Heavy Duty)

Product Details:

- Condition New

- Frequency 50-60 Hertz (HZ)

- Type Heavy Duty Cold Pressure Butt Welding Machine

- Click to View more

Cold Pressure Butt Welding Machine Model-I (Heavy Duty) Price And Quantity

- 1 Piece

- INR

Cold Pressure Butt Welding Machine Model-I (Heavy Duty) Product Specifications

- New

- 50-60 Hertz (HZ)

- Heavy Duty Cold Pressure Butt Welding Machine

Cold Pressure Butt Welding Machine Model-I (Heavy Duty) Trade Information

- Cash on Delivery (COD) Cheque Cash Advance (CA)

- As per order Per Month

- 30 to 75 Days

- Wooden Box

- All India

Product Description

Introduction:

Cold Pressure Welding Process

A Process involving to weld non ferrous metals and their alloys in the wire form, without use of heat, electricity, fillers or flux. It can be used across a range of metals viz., Aluminium, Aluminium Alloys, Copper, Lead, Zinc, Nickel, Silver etc. We BABA ENGINEERING WORKS, are a leading manufacturers of cold pressure Butt Welding Machines for the past 25 years and are having a wide customer base all over India with extremely satisfied customers.

Principle

The technology of cold weld involves bringing in the two surfaces into intimate contact and applying compressive pressure so that faces are stretched to and joined by forming a continuous grain structure for producing a true weld. This is done by bringing wire ends into intimate contact and applying repetitive pressure through Cam Mechanism. Due to this pressure the soft material flows to the outer surface and clear and coplanar surface comes into contact which makes a perfect joint of continuous grain structure.

Metallurgical Explanation

The Surface of clean metal can be considered as one half of a grain boundary since there will always be atoms on the surface outer position that form their ideal lattice structure. Theoretically, if two perfectly clean and coplanar surfaces were brought into contact, the resultant joint would be as strong as the grain boundary and the metal itself.

Applications

The operational simplicity of cold welding technique makes it an ideal process for use in industries where economic efficiency demands the use of unskilled labour. The equipment has a consistent performance with high rate of productivity. In the mass production industries, a cold welding station can be very easily built into a production line. The process has wide scope of application in conductor (ACSR, AAC, AAAC), Cables (Power & Telecom), Enamelled wires, PVC Wires & DPC Wires etc., manufacturing Industries. The joints are mechanically strong and electrically have the same characteristics as the parent metal.

Cold Pressure Butt Welding Machine

The Cold Pressure Butt Welding Machines are manually/hydraulic operated, trolley mounted machines for welding non-ferrous metals in their wire form. Cold Pressure Butt Welding machines are available in five models viz. Model-I, Model-I (Heavy Duty), Model-II, Model-III (Hydraulic) & Model-IV (Hydraulic) with different capacities. The ends of the wires are inserted in the gripping dies and are fed towards each other in small increments by downward movements of the handle. The number of upsets required depends on the original condition of the butting faces but in most cases six incremental upsets are sufficient to form the required interfacial bond. After welding at the joint, there will not be any changes in the material's parental properties and 90-95% tensile strength is retained.

Being a customer oriented organization, we are deeply engaged in offering a wide array of Heavy Duty Cold Pressure Butt Welding Machine which is manufactured using high quality raw material and modern techniques to meet the industrial norms. We provide highly flexible product which has high anti-corrosion strength with easy, reliable and user-friendly operation.

- Is It Portable: Portable

-

Type: Cold Pressure Butt Welding Machine Model-I (Heavy Duty).

- Material: Steel

- Material Grade: Standard

- Surface Treatment: Polished

- Main Export Market(s) : Worldwide

Capacity To Weld:

- Aluminum Wire From 2.00mm To 4.72mm

- Aluminum Alloy Wire From 2.00mm To 4.63mm

- Copper Wire From 2.00mm To 4.00mm

(Excluding Die Set)

- Copper Wire From 8.SWG To 14 SWG

Other Products in 'Welding Machines For Medium Wires' category

GST : 36AAOPR8665G1ZY

|

|

BABA ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |